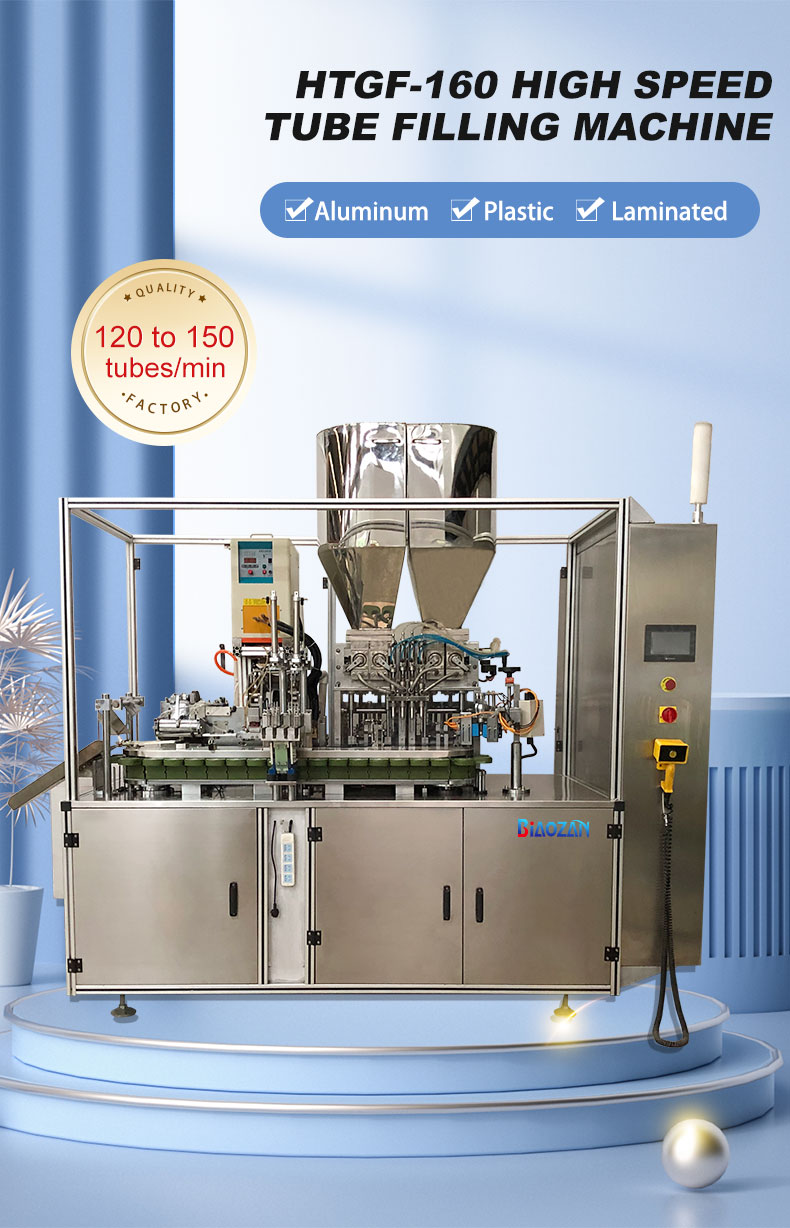

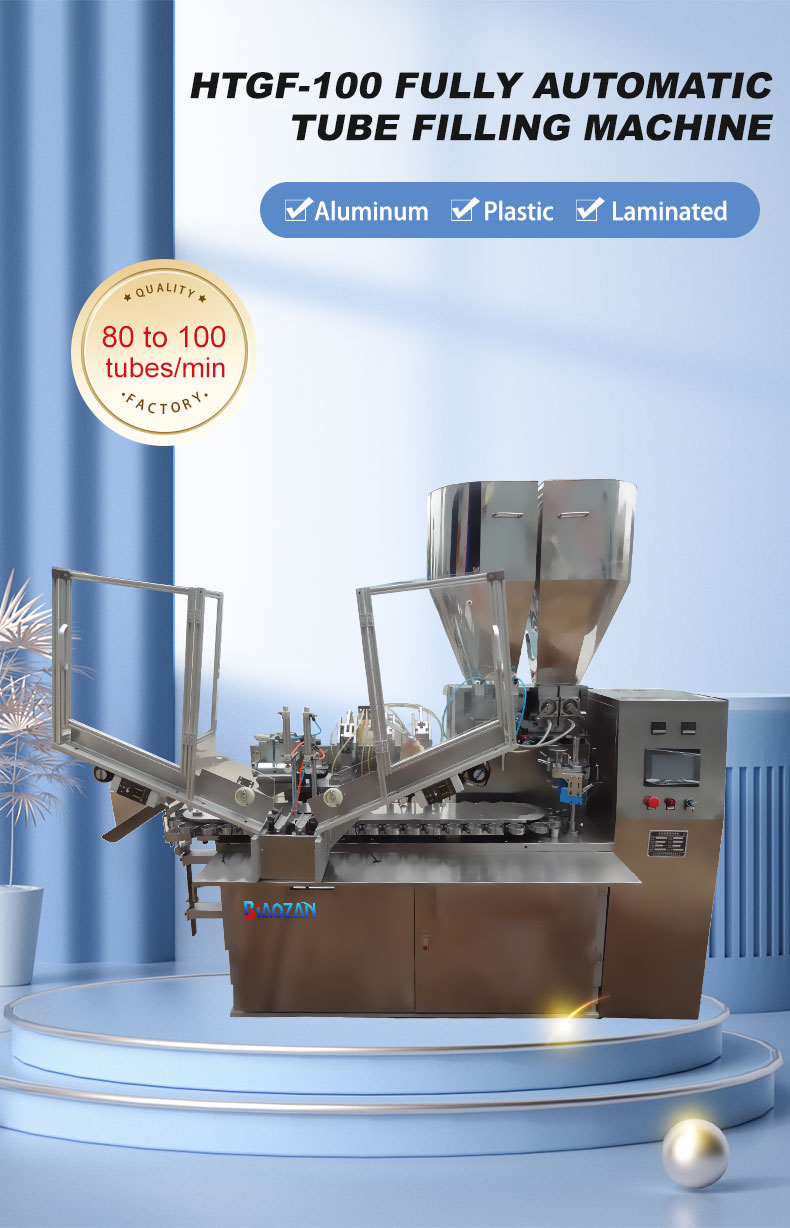

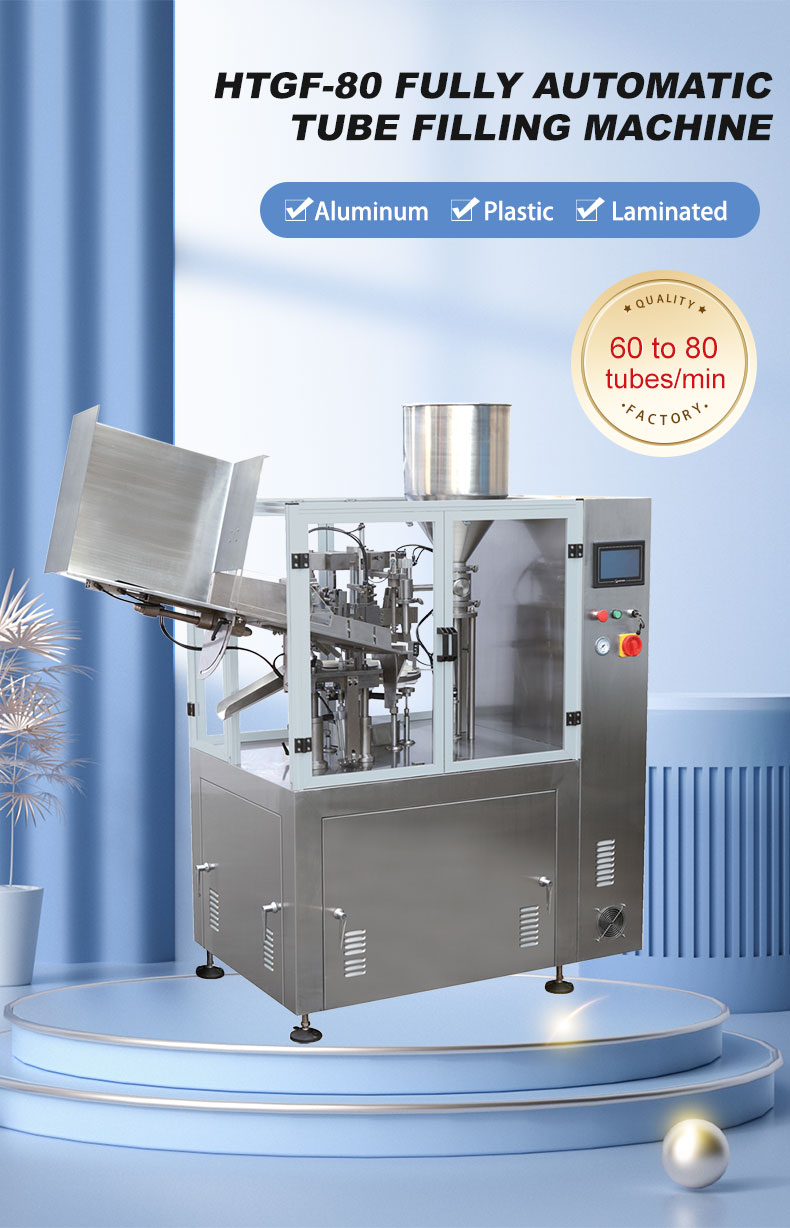

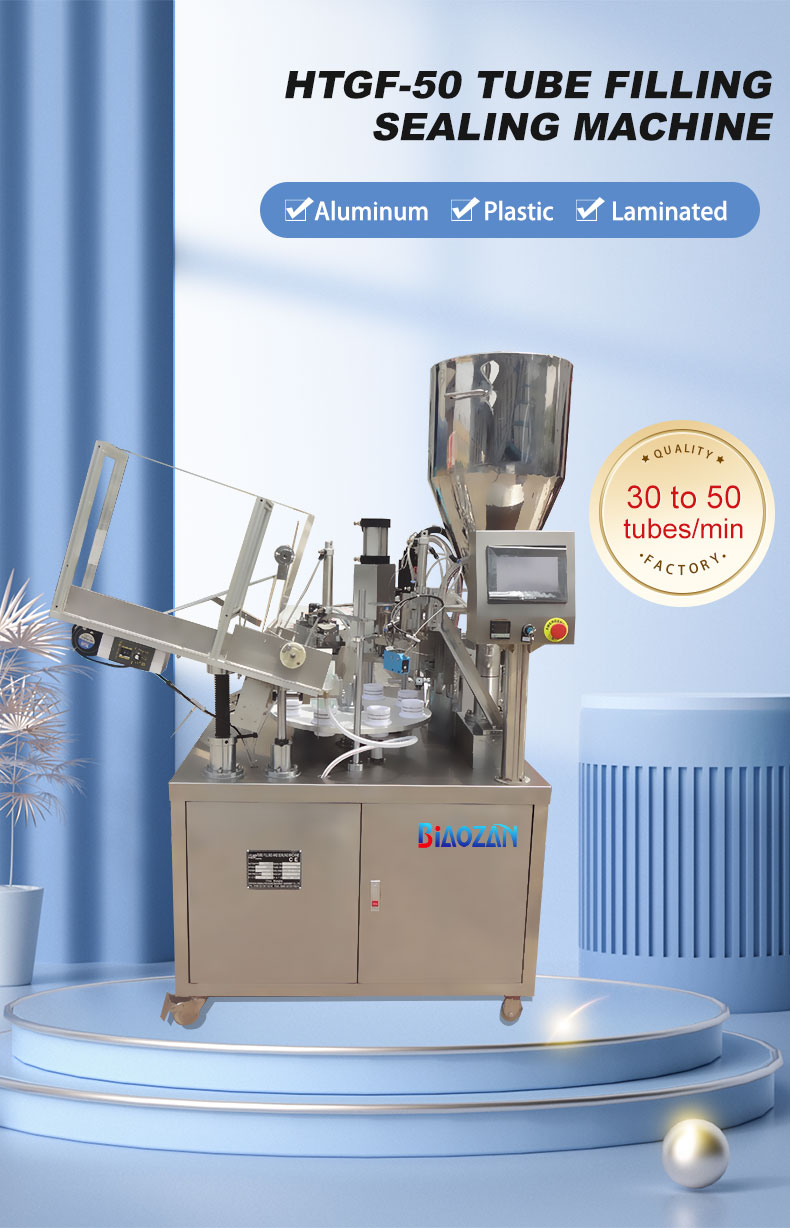

Automatic Tube Filling and Sealing Machine

Automatic tube filling sealing machine is one of our company’s main product series. It can customize equipment with different production speeds of 30-240 tubes/ min according to customer needs. This type of equipment is widely used in: pharmaceutical, daily chemical, cosmetics, food sauce and other industries, and is widely used in filling and packaging production lines for toothpaste tubes.

Product Description

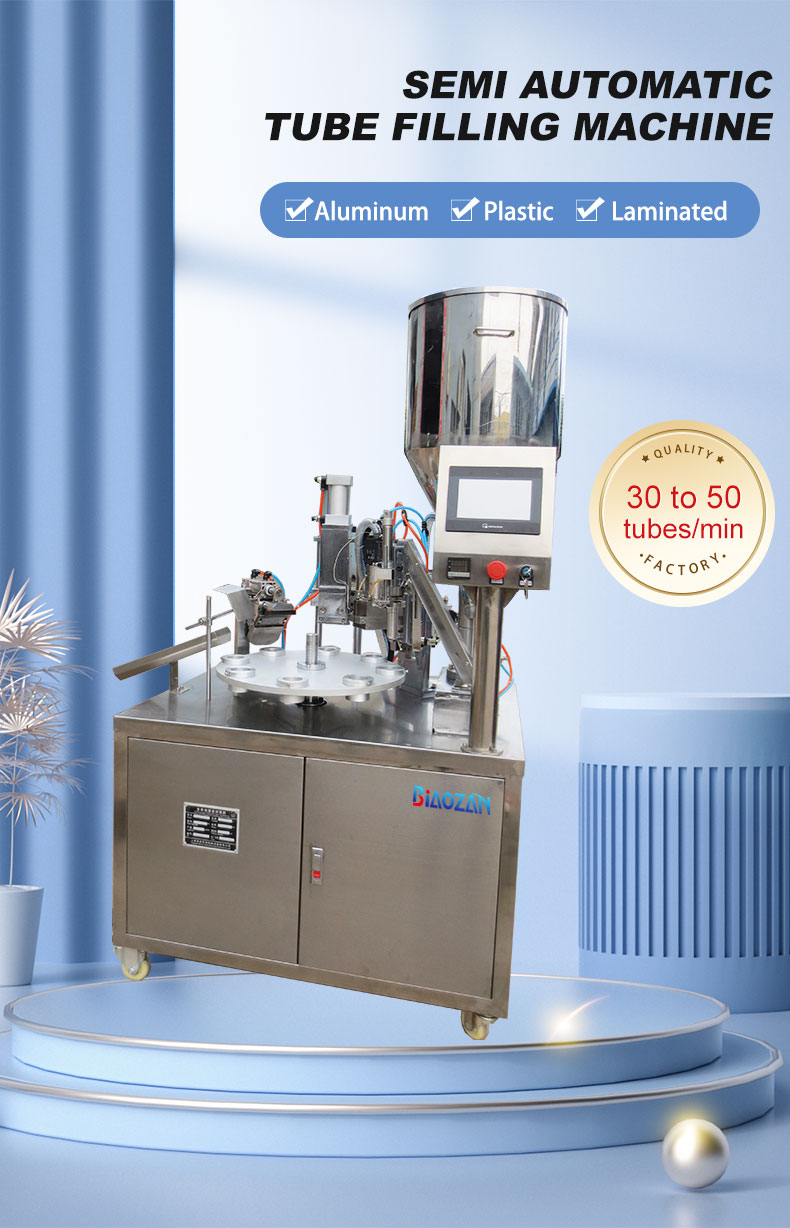

Tube filling and sealing machines come in various configurations, including automatic, semi-automatic, and manual models, to accommodate different production requirements and budgets. Additionally, they may offer customization options for tube size, filling volume, and sealing methods to meet specific product needs.

Working Process

Here’s a basic overview of how a tube filling and sealing machine typically works:

-

- Tube loading: Empty tubes are loaded into the machine’s magazine or hopper. These tubes can be made of various materials like plastic, aluminum, or laminate.

- Tube orientation: The machine orients the tubes in the correct position for filling and sealing.

- Filling: The product to be filled into the tubes is pumped or fed into the machine’s filling mechanism. The filling mechanism then dispenses the product into the tubes in predetermined amounts. The filling process may involve volumetric or weight-based filling, depending on the requirements of the product.

- Sealing: After filling, the open ends of the tubes are sealed to prevent leakage and contamination. Sealing methods may include heat sealing, ultrasonic sealing, or crimping, depending on the type of tube material.

- Coding and marking: Some machines may include additional features for coding or marking the tubes with batch numbers, expiration dates, or other relevant information.

- Inspection: Quality control mechanisms such as vision systems or sensors may be integrated into the machine to inspect filled and sealed tubes for defects or inconsistencies.

- Tube ejection: Once filled and sealed, the tubes are ejected from the machine for further packaging or labeling processes.