Double side labeling machine is designed in a manner that NO maintenance is required for this flat bottle labeler. The bottle sticker labeler works on a single phase ensuring the symmetric working of the conveyor belt, label dispensing and top hold belt system. This equipment is easy to control online with mixed single pot speed control.

The double side bottle sticker labeling machine labels on double sides and can adjust according to varying sizes of labels. The bottle sticker labeler has advanced sensor and control mechanisms that are responsible to work only when the bottles are inserted into the conveyor belt. If the absence of bottles is detected on the belt, the bottle labeler automatically stops the working of the flat bottle labeling machine and does not release the labels further.

Double side labeling machine is simple to use and easy to maintain. This multi-purpose equipment is suitable for applying sticker labels on the front and backside of bottles, jars, etc., which are round, flat, oval, rectangular, or square in shape. It is a multi-pack linear machine with a uniquely designed continuous movement, pocket type bottle alignment system. This double-side labeling machine model is perfectly suitable for applying labels on both sides of bottles and containers of various shapes and sizes. It has an output of up to 120 labels in a minute, based on the label and product size.

The labeling speed is also dependent on the stable motion of the product on the conveyor of the equipment, at a relatively higher speed. Further, the automatic product alignment system is fully synchronized with the top holding belt system, to provide maximum stability and vertical positioning of the bottles with different shapes. It even incorporates the most modern label dispensing system and a simple sensing system for labels and products.

Features

- Adopt mature PLC control system technology, make the whole machine stable and high-speed.

- Use a touch screen control system, make operation simple, practical, and efficient.

- Upgraded butterfly labeling station design, can be applied for conical bottle labeling.

- Screw adjust the suppression mechanism, high accuracy.

- Synchronization chain mechanism, to ensure smooth and precise calibration.

- Transparent sticker labeling without bubble, adhesive sticker labeling without a wrinkle.

- Widely used and multi-function with high flexibility.

- Inkjet code printer is optional.

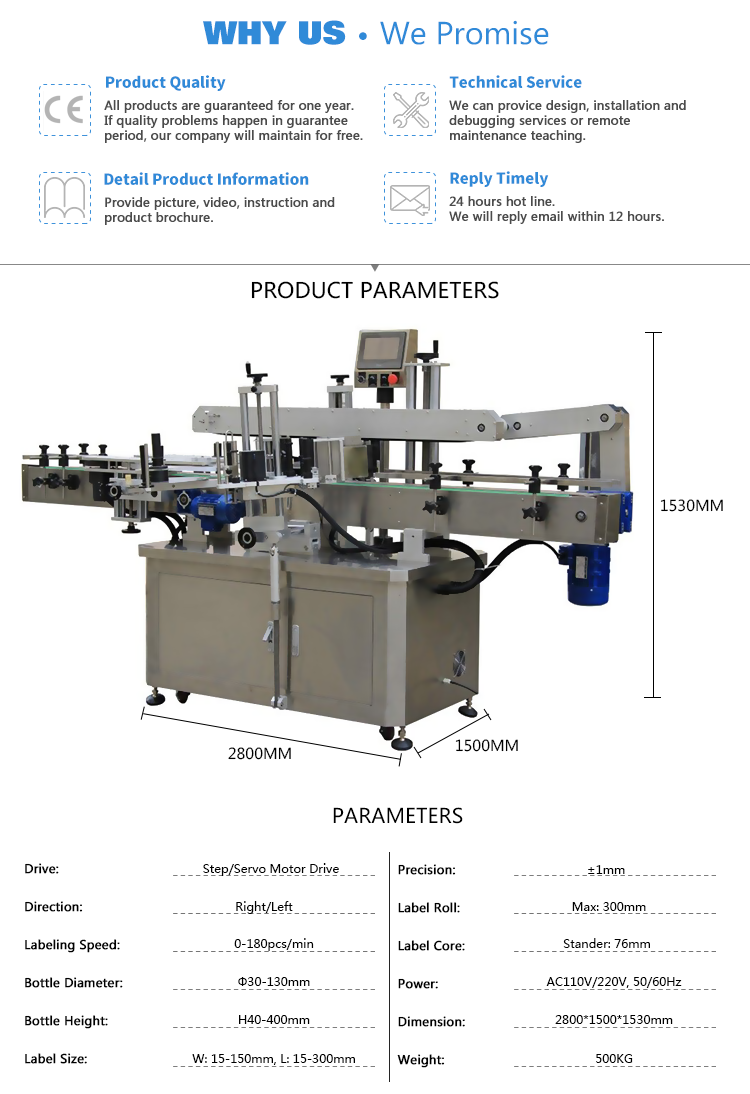

Specifications:

| Model | BZTB-DS |

| Labeling Precision | ±1mm |

| Labeling Speed | 60-120pcs/min |

| Object Size | 30-280mm(H), 30-100mm(W) |

| Label Size | 25-300mm(L), 20-180mm(W) |

| Roll Size | 76mm(Inside), 300mm(Outside) |

| Voltage | AC110/220V, 50/60HZ |

| Power | 2KW |

| Machine Size | 2400*1450*1360mm (L*W*H) |

| Machine Weight | 500KGS |