Linear filling capping machine, which combines filling, putting a cap, capping, and output in one machine. It adopted advanced technology, using PLC and electronic fiber optic sensor control. There is bottle filling, no bottle stop, and a counting function to record the production. The filling heads and capping heads can be customized according to your requirements.

This automatic linear filling capping machine is mainly used for various liquids or flow material filling and capping. The surface and material of the equipment are made of 304 stainless steel according to the contact surface, with no dripping, no drawing, and easy to clean, in line with GMP requirements. Mainly used in pharmaceutical, medical, food, chemical, and other industries tinctures, syrups, and all kinds of wine, oils, and other liquid fillings.

Linear filling capping machine meets the hygienic standard of GMP. The electric part of the filling machine adopts domestic and famous brands, it has some features such as technological advance, high automation, ease of operation, and reliable performance, compared with domestic similar products, this filling machine has a smaller volume, lighter, elegant appearance, thorough disinfection, so it can prevent the air pollution effectively, guaranteed that the product has high quality.

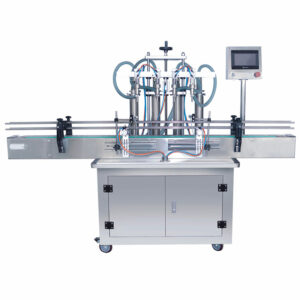

In the filling part, there have several filling heads, the technology is based on introduction and digestion from aboard advanced technology, innovation, and development to advanced level of filling equipment. The features are such as advanced structure, smoothness, reliability, ease to operation, can be variable speed, and high efficiency.

Working Principle

- Filling: via a conveyor belt to carry the bottom of the bottle to the filling head and the bottle was blocked by the dial to step forward, this time four synchronous filling heads were into the bottom of the bottle and complete filling by a quantitative piston pump.

- Put Cover: caps vibrate through an electromagnetic oscillator, so cover up the delivery chute, through the bottle fell to the track, and then was pressed by the press head.

- Capping: filling finished bottle-fed by a conveyor belt on the turntable, the turntable through the sheave box for intermittent operation. When a bottle with a cap is carried to the bottle caper housing for intermittent pauses, the capping head will be pressed lower by a cam and rotate clockwise, thus boosting the cap tightened.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net